Casing Wearing Sub

The Non-rotary Casing Wear sub consists of body, non-rotary sleeve, retainer ring and screws. The interface between integral body and non-rotary sleeve is coated hardness chrome for corrosion and abrasion resistance. The joint may reduce the friction between drill pipe and casing during drilling, and may reduce the loss of torque. So it is useful for preventing casing and drill pipe from tear and wear.

Classification:

Detailed Description

APPLICATION

The Casing Wear Sub consists of body, wear sleeve, retaining ring. The interface between integral body and wear sleeve is coated hardness chrome for corrosion and abrasion resistance. The casing wear sub may reduce the friction between and casing and drill pipe during drilling, and may reduce the loss of torque. So it is useful for preventing casing and drill pipe from tear and wear.The Casing Wear Sub is installed at the drill pipe tool joint area. During drill pipe rotation, the sub's body rotates synchronously with the drill pipe. A low friction coefficient coating is applied between the body and the wear sleeve, minimizing relative motion. When the wear sleeve engages the casing inner wall, it either maintains static contactor exhibits minimal relative rotation/friction. This mechanism effectively reduces rotational wear between the sleeve and casing, thereby minimizing casing damage during tripping operations and rotating drill string processes.

FEATURES AND BENEFITS

1. This Casing Wear Sub demonstrates superior friction and torque reduction performance, achieving approximately 20% reduction in frictional resistance and 30% decrease in torque.

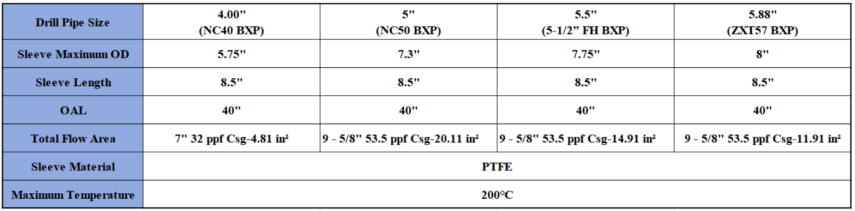

2. The wear sleeve is adopted with enhanced PTFE material, with temperature resistance up to 200 ℃.

3. The wear sleeve exhibits an extended service life ≥ 500 operating hours under standard drilling conditions.

4. Enhances drilling efficiency by lowering drill string torque loads and improving safety margins during operations.

5. Delivers cost-saving benefits through accelerated drilling speeds and reduced overall operational time. 6 . Simplified installation and replacement procedures, can be operated on the construction site.

TECHNICAL DATASHEET

Previous Page

Next Page

Previous Page

Turbo Drive Agitator

Next Page

More products

MESSAGE

PETROZHR

Official Website QR Code

Tel/ Whatsapp:(+86)18946707699;(+86)18783877999

Fax: (+86)838 5701707

Address:Building 23, Deyang Science and Technology Island, No. 16 Yangjiang Road, Guanghan City, Deyang City, Sichuan Province

E-mail: liupeng@petrozhr.com; liudd@petrozhr.com

All rights reserved:©Sichuan PetroZHR Petroleum Machinery Engineering Co.,Ltd 300.cn

SAF Coolest v1.3.1.1 设置面板 WZBSX-AFJB-ZZSZE-ZZQ

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page